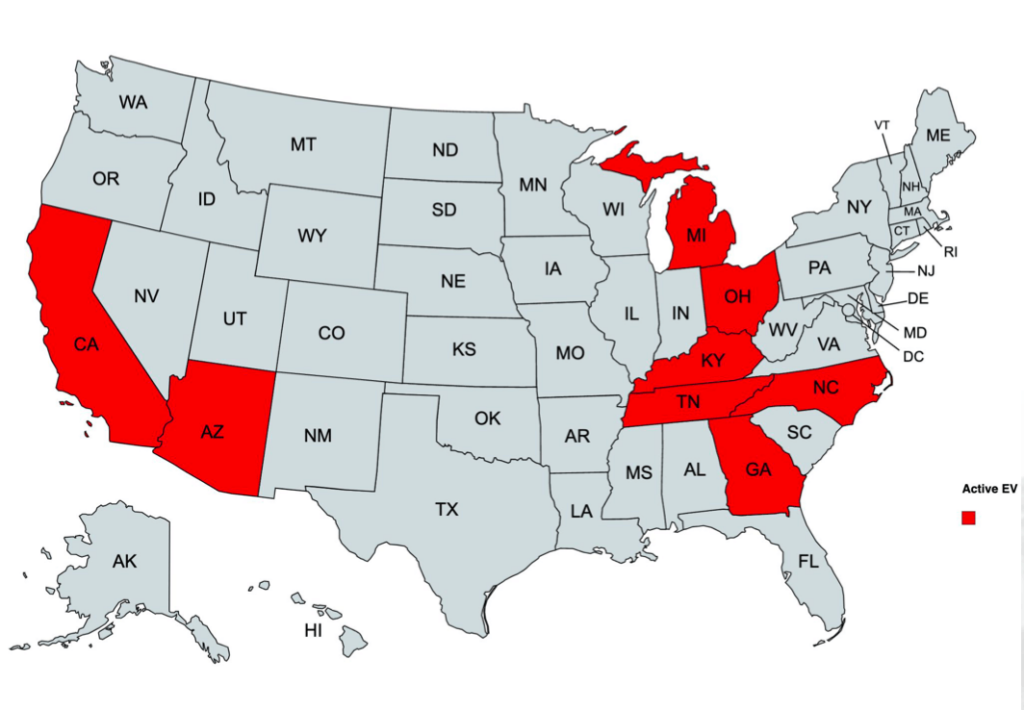

The electric vehicle market is growing, and it is happening right in our own backyard. Between the increasing demand for electric vehicles and the push for domestic manufacturing, there is a lot of work to be done to outfit the United States to supply the market. There are some states that are particularly active in the growth of manufacturing components for electric vehicles. These states include Kentucky, Michigan, Ohio, Tennessee, Georgia, North Carolina, California, Texas, and Arizona, to name a few. These states are involved in producing batteries, electric drivetrains, electric motors, power electronics, and research and development facilities also focused on advanced electric vehicle technologies. Many of these states are building facilities to manufacture electric vehicle components are located near original equipment manufacturers (OEMs).

That is where we come in to design and build the facilities, as well as install the

equipment.

We are currently designing and building a facility in Elizabethtown, Kentucky for ANP Enertech that will manufacture components that are critical to the fabrication of the electric vehicle car battery. You can read more about this below. We supply the suppliers with facilities built and engineered from the ground up — from start to finish — so they can manufacture their supplies for the electric vehicle market.

From an industry standpoint, we understand that electric vehicle component manufacturers consider proximity to auto manufacturers, access to skilled labor, government incentives, and a solid supply chain important factors in determining where to build their electric vehicle component manufacturing locations. That is why they partner with us.

We develop and follow electric vehicle manufacturing projects the whole way through. We call it Design/Build+. We do Design/Build construction, plus other services and sourcing to make the facility operational. Our international clients particularly like working with us as a full-service partner.

Design/Build+ includes:

Design-Build + Press Pits and Machine Foundations

Design-Build + Equipment Procurement

Design-Build + Equipment Installation

It’s a turn-key solution with our intellectually rigorous team behind the work to deliver a high- quality facility on-time and on-budget. Our experience in working with electric vehicle manufacturers is valuable to both our team, our clients’ teams, and their customers or end- users. Building an electric vehicle manufacturing facility is a significant investment, and selecting the right design and construction partner is crucial for the success of the project. We do not take that lightly.

So, how do we build leading-edge facilities for electric vehicle manufacturers?

- We research, define, and develop the project requirements with the client.

- We are connected in the communities we build in, which allows us to collaboratively and effectively serve our clients and the project effectively end-to-end.

- We are the perfect-sized company for manufacturing facilities. We are a large enough company to provide the stability and the capability to build a facility, while offering our clients direct access to our engineers, architects, project managers, and the rest of our team on the project.

- Electric vehicle manufacturers do have industry-specific needs. We understand that.

- We have been designing and building industrial projects for over 26 years.

- We are well-versed in energy-efficient designs and renewable energy integration.

- Being on-time and on-budget is incredibly important to us, and so is quality and compliance.

ANP Enertech

We are leveraging all of these value-adds unique to Bristol Group to build ANP Enertech’s state- of-the-art electric battery components manufacturing plant. We are proud to outfit ANP Enertech with a facility to successfully support this large initiative. Download our one-page case study here.

“It has been a true pleasure working with the ANP Enertech team. From early design concepts through construction, their team has been engaged and very responsive. Through this collaboration we were able to fast-track their project, which will allow the company to manufacture their components months earlier than a typical design-bid-build approach. Through Bristol’s Design-Build-Plus concept we have also fast-tracked ANP’s equipment procurement and install process. When we combine design, construction, pre-manufactured building components, equipment procurement, and equipment install, we can deliver projects to our clients faster than anyone in the market. We are honored to be a partner to ANP and help them achieve their goals.”

— Trevor Bing, Preconstruction Manager

Let’s build an electric vehicle manufacturing facility—together.

The electric vehicle movement is here to stay, and we are here to help design and build it.

Contact our team to learn more about how we work and the innovative projects we can do together.